A forward-looking success

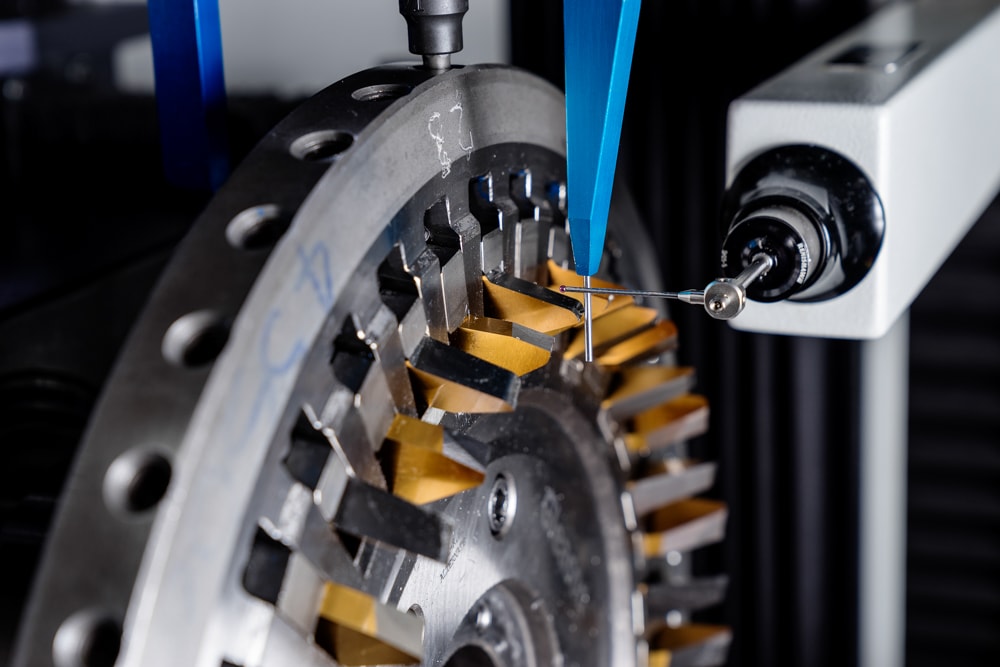

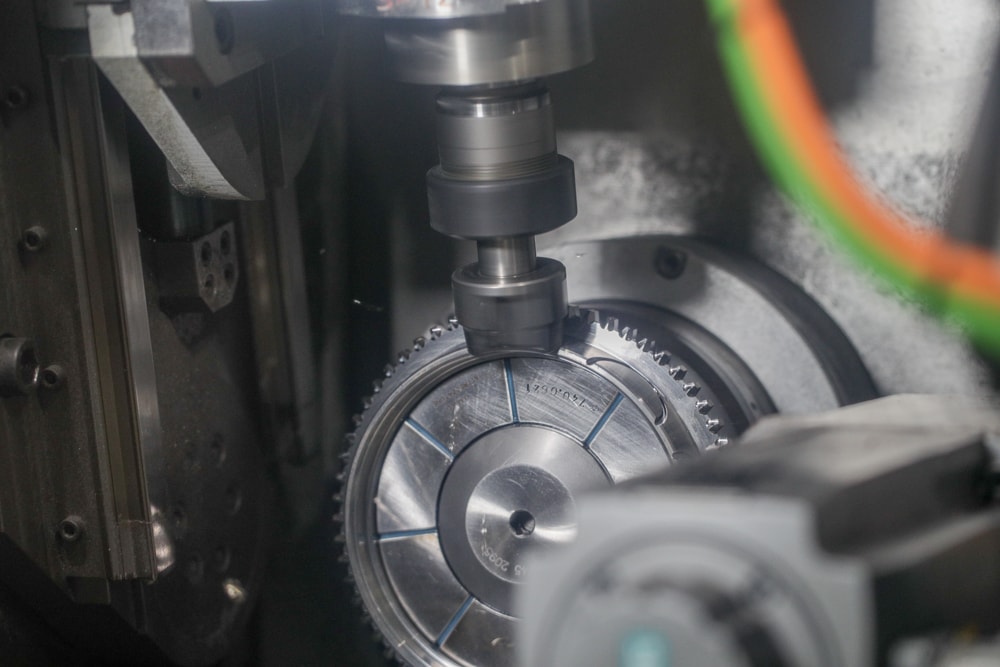

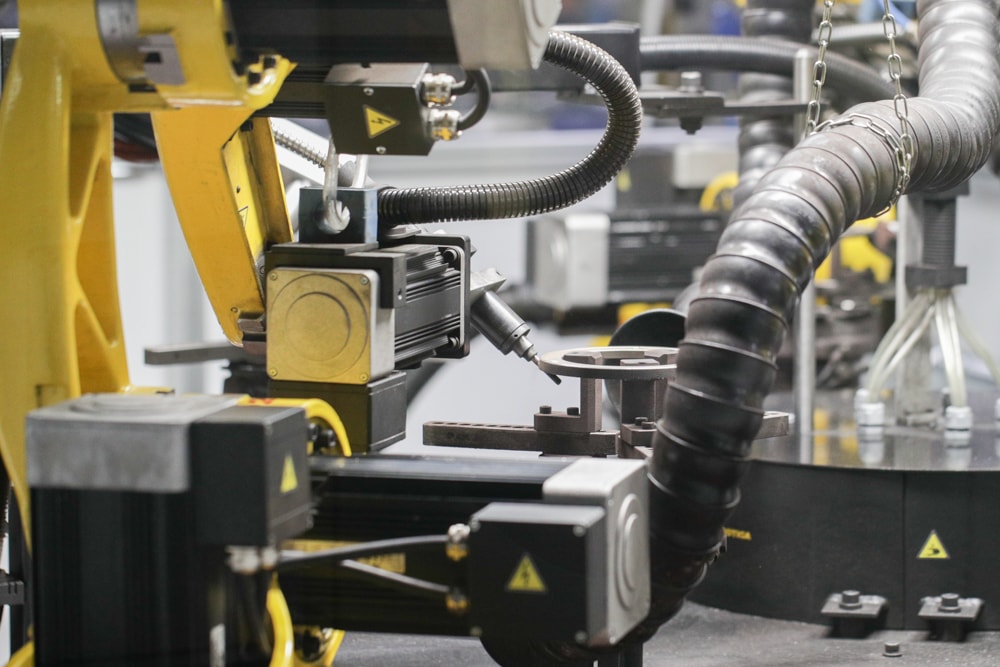

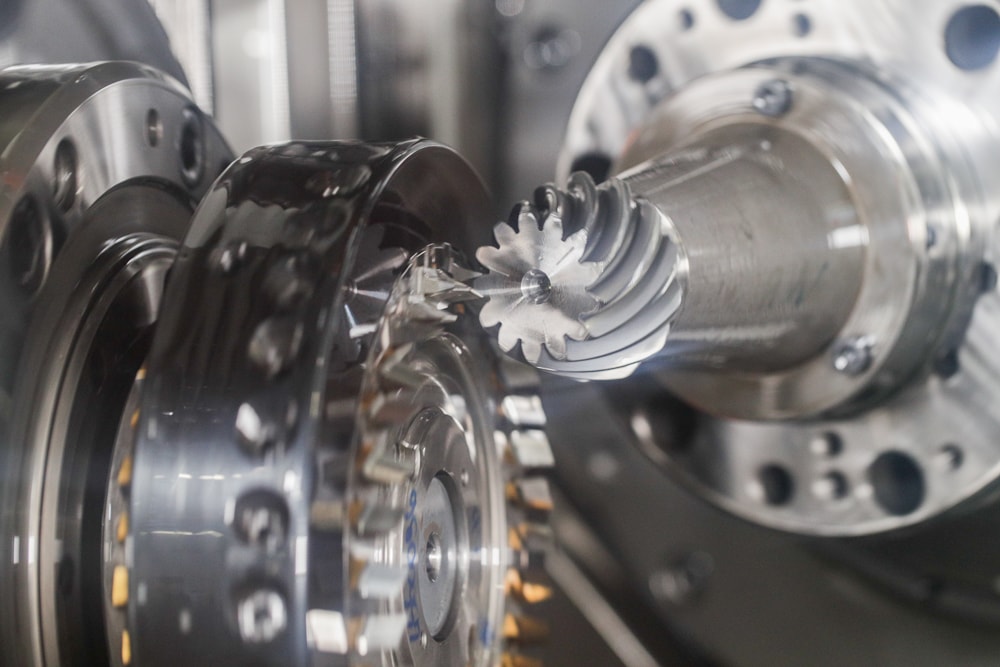

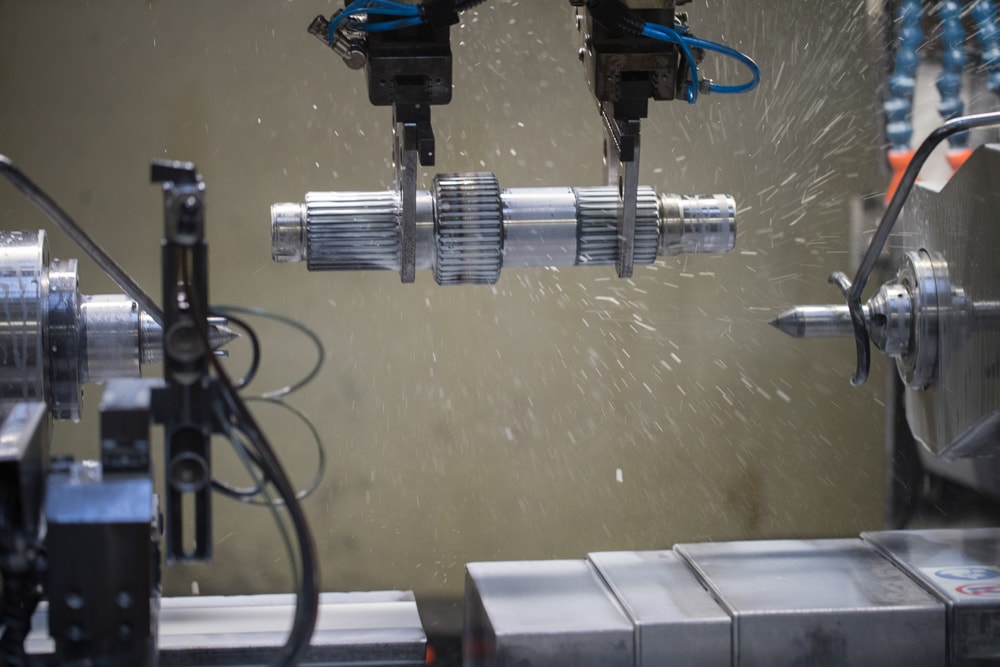

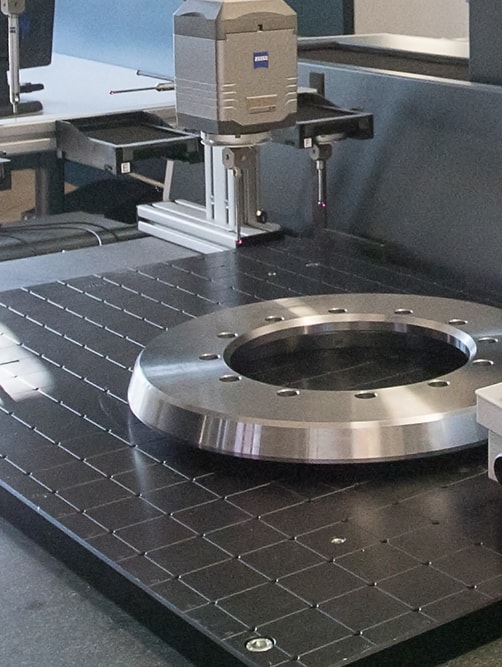

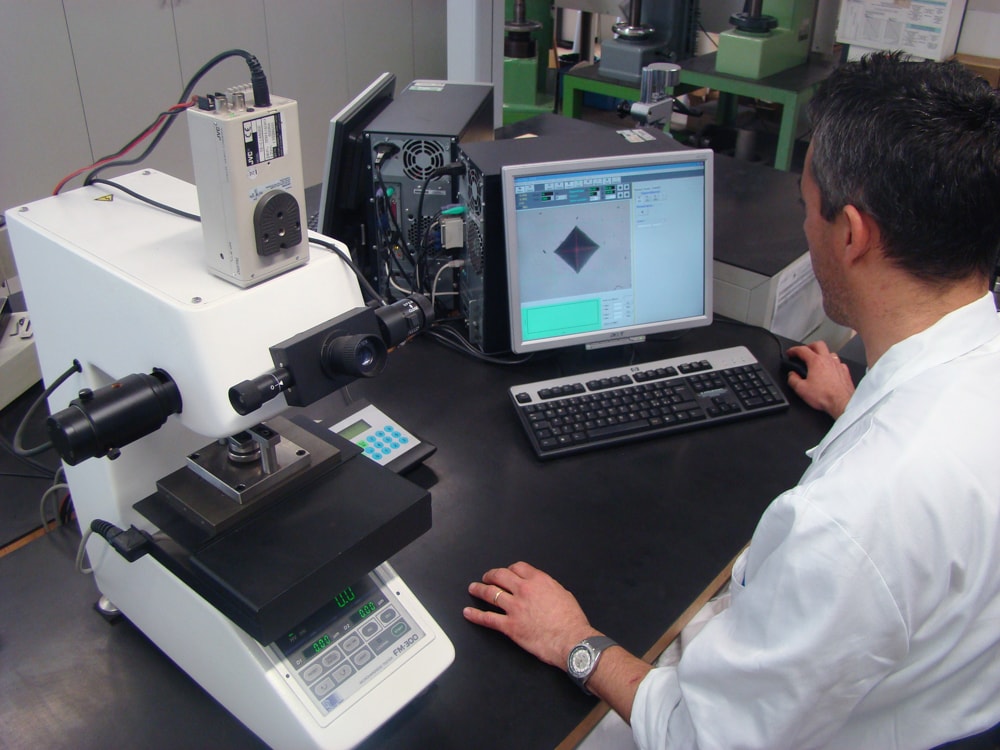

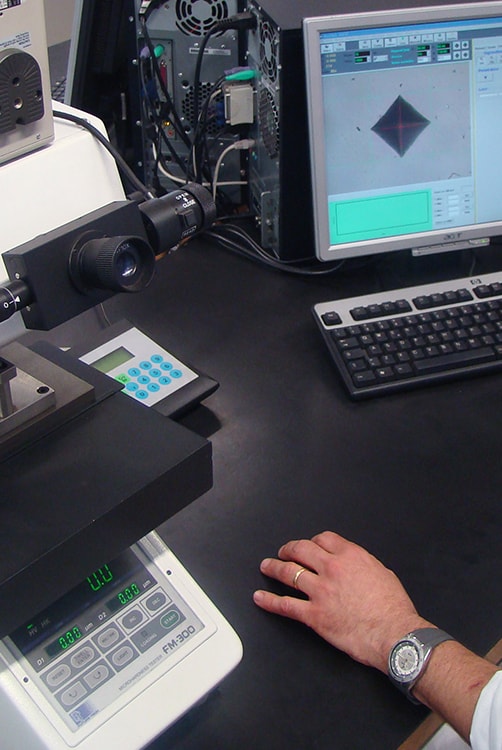

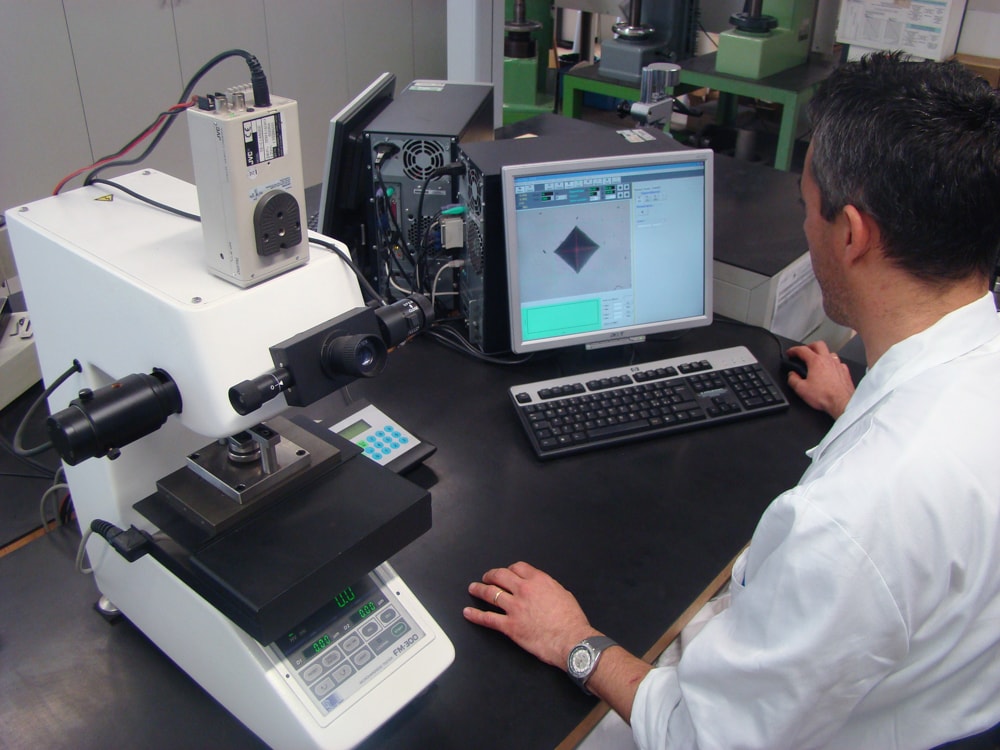

Technological innovation lies at the heart of our success. This is why our spare parts are manufactured using the most advanced production systems, with overnight cycles managed by automated machinery requiring no supervision and advanced methods to constantly ensure the reaching of the required quality standards. We invest in new production systems to maintain our competitive edge ultimately defined by our pursuit of continuous improvement.

13 types of manufacturing processes internally managed

- Turning

- Toothing

- Routing

- Grinding

- Tooth grinding

- Running-in

- Metallisation with molybdenum

- Carbon fibre coating

- Electronic beam welding

- Shot peening

- Heat treatment

- Fitting

- Packaging

Constantly improving

We invest in new production systems to maintain our competitive edge ultimately defined by our pursuit of continuous improvement.

- Gleason, Liebherr and Pfauter gear cutters machines

- Emag and Muratec lathes

- Wera Profilator machining centres

- ALD heat treatment plant

equipped of 8 vacuum furnaces with electrical power and double quenching system, high pressure gas or oil. - EMA inductive calibration hardening machine

with quenching under inert gas.